It is surprising how much a closer look at these supposedly boring pallets is worthwhile. They have long since shed their reputation as simple storage aids and have advanced to become hip upcycling objects that are conquering community spaces, living rooms and art galleries. But how did it come about that the Europallet, of all things, became hype?

This is an exciting question that does refer to the past. Because the digital future also has a lot in store for pallets. Modern variants come with trackers and are really “smart”. They report regularly and have long since become a “heroine of transport”.

So, what is behind the simple pallet shape, and what role will it play in the digital future? A question that is not only interesting for logistics experts. Because, who knows, maybe there is even more hidden in the inconspicuous pallet than previously suspected?

© Pixabay

Outline of the history of the palett

Admittedly, the development of the pallet does not go back to the age of the dinosaurs. Nevertheless, its development has a long and fascinating history that can be easily reconstructed.

As early as 500 BC, there is evidence of using wooden sledges and skids to transport building materials. One impressive example is the pyramids, which were built thanks to such means of transport.

The palette gradually developed in the following period, which spans several centuries. Experiments with various means of transporting and storing goods – from boxes and barrels to crates and sacks – preceded this development. It was not until the introduction of standardised transport containers, such as the predecessors of containers, and the invention of the forklift truck at the beginning of the 20th century that the movement of goods and storage systems became truly efficient.

The pallet played a leading role in this, as it could be used as a simple yet robust means of transporting various goods. The introduction of pallet standardisations made it possible to integrate them more efficiently into the flow of goods. It made them easier to handle by forklift trucks.

It is impressive how the simple pallet has developed into a vital component of modern logistics and storage systems. Furthermore, it will continue to play a significant role in the digital future.

© Pixabay

However, the American company Clark Equipment invented the forklift truck in 1920 is considered a logistical milestone. But to exploit this machine’s full potential, another transport innovation was needed. As early as 1924, Howard T. Hallowell applied for a patent for the “Lift Truck Platform” – one of the first pallets ever. Until the 1930s, further patents were filed, gradually leading to the development of the transport pallet as we know it today.

Incidentally, the “Europallet” takes its name from its creation and standardisation in Europe. In the 1960s, it was developed by the European Pallet Association (EPAL) to simplify the transport of goods. EPAL controls and regulates Europallets’ production, maintenance, and exchange in Europe and worldwide. Due to their standardisation and robust construction, Europallets are used in various industries and sectors. They are often preferred over other types of pallets. However, it should be noted that different standardised pallet types are widely used in other regions of the world, such as the “GMA pallet” (Grocery Manufacturers Association) in North America or the “Australian Standard Pallet” in Australia.

© Pixabay

Alles Paletti?

In the world of logistics, pallets are indispensable in the modern transport industry. With a wide range of variants and dimensions, there is a suitable model for every application. Pallets are differentiated according to their construction, including 2-way and 4-way pallets. The latter can be driven under and lifted from all sides, which makes them easier to manage. There are also special pallets for specific requirements, such as cleanroom pallets. These are usually made of washable and disinfectable metal or plastic.

Unlike one-way pallets, reusable pallets are typically more stable and part of an exchange system. The best-known reusable pallet is the Europallet, which can be recognised by its EPAL seal. This standardised pallet with rounded edges can carry up to one tonne. However, if you plan to build furniture from pallets, you should look for the IPPC seal for pest-free wood. Moreover, the corner and centre blocks should be made of solid wood and not pressboard. Pressboard tends to crumble when damp, while solid wood is more durable and resilient.

© EPAL

The Big Player: EPAL

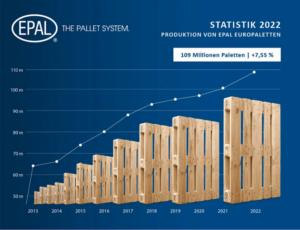

The European Pallet Association e.V. (EPAL) is looking forward to the 2022 business year with satisfaction. As the association announced, the production of Europallets increased to a record value last year.

A total of 109.05 million Europallets were produced, corresponding to a growth of 7.55 per cent or 7.65 million EPAL Europallets compared to the previous year. In 2021, well over 100 million new Europallets were produced in a calendar year for the first time. The success of EPAL shows once again that Europallets continue to play a significant role in transporting goods and are in high demand.

But the pallet is “making its way”; it is being further developed and adapted to the current needs of modern logistics.

© EPAL

Plastic pallets H1: Industry standard for hygiene

The H1 plastic pallet, also known as a hygiene pallet, was developed to meet the high food, pharmaceutical and chemical requirements. It meets strict hygiene standards and is ideal for transporting sensitive goods. With a standard size of 1200 × 800 mm and a load capacity of up to 1250 kg in high-bay warehouses, the H1 pallet is ideally suited to the needs of the logistics industry.

The pallet is made of HDPE (high-density polythene) or PP (polypropylene), which makes it particularly resistant to chemicals, UV radiation and temperature fluctuations. It is also easy to clean as it has no nails, splinters, or sharp edges, as can be the case with wooden pallets. The smooth surfaces and closed runners allow for easy cleaning and prevent dirt or bacteria from entering.

Another advantage of the H1 plastic pallet is its repairability. In case of damage, individual components can be easily replaced, extending the pallet’s life cycle and conserving resources. The disposal of H1 pallets is also environmentally friendly, as they are 100% recyclable and can be returned to the material cycle.

© Trans-o-flex

Other pallet standards

In addition to the well-known Europallet, other widely used pallet standards have become established regionally or industry-specific.

The so-called “GMA pallet” (Grocery Manufacturers Association) is widely used in North America. It has a standard size of 48 × 40 inches (approx. 121.9 × 101.6 cm) and is often used in food and retail.

The Australian Standard Pallet is commonly used in Australia and measures 1165 × 1165 mm. Due to its size and stability; it is adapted for the Australian market and the specific needs of the industry there.

Another example of standardised pallets is the ISO pallet, which is based on international standards. These pallets are available in six sizes and have been defined by the International Organisation for Standardisation (ISO). They are designed to be transported efficiently in standard ISO containers, facilitating the international movement of goods.

Quo Vadis, Europallet?

The pallet is and will remain integral, especially in logistics and merchandise management. It is impossible to imagine life without it. With an estimated 350-500 million EPAL-licensed pallets in use and an unimaginably high number of other pallets from various manufacturers worldwide, the pallet is indispensable from today’s and tomorrow’s perspectives. Whether manufacturing industry or trade – no one can do without them. This proves that the simplest things often bring the most significant benefits and worldwide success. The history of the pallet impressively proves how a seemingly simple object has revolutionised the global economy. Today, the pallet is one of the most important achievements in logistics. It has helped to make transporting goods easier, faster, and more efficient.

The future of EPAL faces some challenges and opportunities. While wooden pallets continue to hold a significant market share, environmentally friendly alternatives such as the H1 mentioned above plastic pallets are gaining importance. To compete, EPAL is focusing on sustainability and digitalisation. For example, in 2018, the organisation launched a pilot project to introduce NFC (Near-Field Communication) chips into its pallets to make pallet exchange more efficient and transparent.

In addition, EPAL has taken measures to make its wooden pallets more sustainable. The PEFC seal (Programme for the Endorsement of Forest Certification) guarantees that the wood used comes from sustainably managed forests. These efforts help reduce the environmental footprint of EPAL wooden pallets and meet the increasing demands of the logistics industry. To continue to meet the needs of the industry, EPAL needs to focus on innovation and adaptability while highlighting the benefits of wooden pallets to compete with alternative pallet types.